8617862265069

Balanced control of hydraulic speed

Section 1 Shock and Reliability of Hydraulic System

The hydraulic balance valve is on the hydraulic balance circuit, which can generate a certain back pressure, which is used to balance the weight of the actuator under the overload condition, and prevent the moving parts of the actuator from falling freely due to the influence of gravity, causing serious accidents, so as to achieve control A component that implements lowering speed and increases overall hydraulic stiffness. The hydraulic balance valve is mainly used in the working conditions where the load force and the load movement direction are the same. The hydraulic balance valve balances the load force in the form of damping to achieve the purpose of stable load movement speed. Therefore, various construction machinery, new energy vehicles and their aviation Hydraulic balance valves are commonly used in the aerospace field. The stability, reliability and system efficiency of a hydraulic circuit containing a hydraulic balance valve often depend on the performance of the balance valve.

At the beginning, in order to achieve the purpose of stabilizing the falling speed of the load, a throttle valve was connected in series in the circuit, which was accompanied by an increase in the power loss of the system and a decrease in economy. The valve is paralleled with a one-way valve, which passes through the one-way valve in the forward flow, and passes through the throttle valve in the reverse flow, which reduces the power loss to a certain extent, but the simple parallel connection of components cannot meet the needs of the system. With the development of manufacturing technology and hydraulic technology, people found that the one-way valve and the throttle valve are integrated, which not only reduces the size and simplifies the structure, but also improves the performance. This is the balance valve produced by various manufacturers. Although there are many types of balancing valves with complex and different structures, these balancing valves still have the functions of check valves and throttle valves. The functions of the check valve mainly include the following two points: fast flow through the forward flow and blocking of the reverse oil passage when the load is maintained. The throttle valve realizes the steady drop of the load by changing the damping of the throttle opening under the condition of load drop.

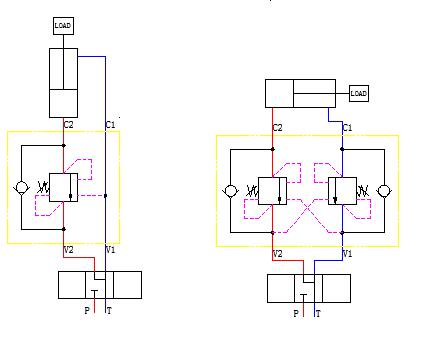

Fig. 1 Single-acting counterbalance valve Fig. 2 Double-acting counterbalance valve

A counterbalance valve is an adjustable valve that allows flow in one direction (V2 to C2), opening in the opposite direction requires a

The pilot pressure control is realized, the opening size of the valve is proportional to the pilot pressure, the valve group includes a check valve, allowing the liquid

The flow is one-way flow, the pilot piston of the relief valve is controlled by the pilot pressure, and the set pressure of the relief valve is lowered to control the reverse flow.

These valves lock the load in a leak-free manner and are ideal for many clamping function applications, as well as preventing the reverse load from stalling and dropping in the event of a hose failure. For falling loads, these valves provide improved health control in most systems because they sense the true pressure of the load all the way to avoid overload conditions.

For pairs of cylinders, counterbalance valves can be used: the pilot pressure will first open the valve at the most loaded cylinder, allowing the load pressure to pass to the other cylinder, while the corresponding valves, which are still closed, require a larger load than would otherwise be required. Small pilot pressure can open.

For best safety performance, these valves should be mounted close to the actuator, either flange mounted or pipe mounted

TEL:8617862265069

FAX:8617862265069

MAIL:info@cndieselpart.com

Copyright © 2025 CNDIESELPART. All rights reserved. Technical support:CNDIESELPART.

8617862265069

8617862265069  info@cndieselpart.com

info@cndieselpart.com  English

English